One of the biggest innovations in the process manufacturing industry is MPC. This is an advanced control technique especially

engineered for process plants to serve its purpose. As a matter of fact, chemical plants have been using this method since the

1980s.

What Is Model Predictive Control?

The Model Predictive Control (MPC) is a system engineered to solve & optimize an underlying control system while satisfying

a set of restrictions. MPC is one of the most predominant advances commonly used in process industries, especially in

chemical plants and oil refineries.

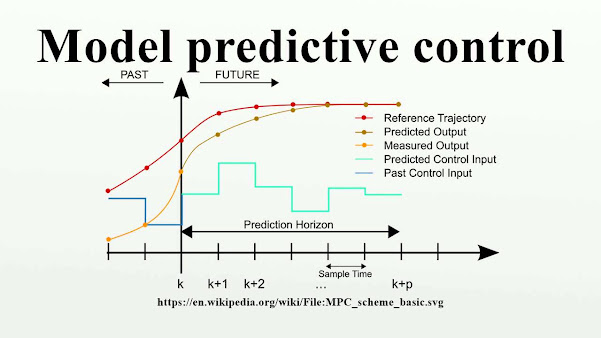

This control system is applicable to a wide range of application systems because MPC is an optimization-based process system.

The technique used predictions from a model to determine the control inputs. That’s why the system is called Model Predictive

Control (MPC).

The models used in the MPC system are basically intended to represent complex dynamical system behaviors. The system is

controlled by PID controllers who are experienced and competent.

The Primary Objectives Of The MPC System Are

To improve the operational efficiency, quality, and productivity of a process plant

To enable a safe and stable operation system

To decreases variability in the key variables by rejecting disturbance

The Significant Importance of Model Predictive Control

Back in the day, MPC was only used by chemical and oil refinery industries. But now, this system is used by power plants.

The biggest advantage of MPC is that it allows the present timeslot to be optimized conveniently. This can be achieved by keeping

the future timeslot in the account.

The MPC is a successful industrial implementation, meaning the system is commonly used in industries that deal with

manufacturing processes. There are many successful industrial implementations that have been reported with the MPC system.

According to reports, the number of industrial applications is expected to increase significantly.

Below are some of the areas where the MPC system is actively used-

Steam generator

Superheater

Pulp and paper industries

Oil refinery plants

Utility boiler

Distillation plants

Hydrocracker reactors

Benefits Of Using The Model Predictive (MPC) system

Extremely beneficial for chemical processing applications

Increase in the consistency of quality work

Control inputs can be determined easily

Maximize in productivity

Minimizing the cost of operating system

Manipulated and controlled variables can be processed seamlessly

Monitor the timeslot conveniently by optimizing when necessary

The requirement for consistency in the quality, operational efficiency of applications, and increasing awareness of the environmental

responsibilities have led to the development of application systems within manufacturing plants. That’s the reason the MPC system.

has been developed.

This step had an enormous impact on industrial plants of every type. The Model Predictive Control (MPC) technique is serving its purpose gracefully and efficiently.

To learn more about Model Predictive Control (MPC), Advanced Process Control, and PID technology system process, visit the

website https://www.picontrolsolutions.com/. Know about our services and products by exploring the website.

You can also get in touch with the experts to enroll in a course or become a business partner. We would love to hear from you.