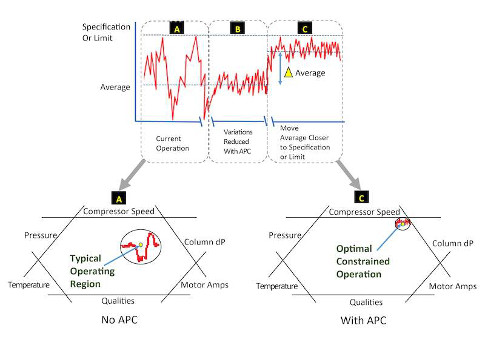

Implementing modern control techniques is vital to enhance productivity and profitability. Advanced Process Control (APC) is a cutting-edge technology that helps in maximizing operational performance, enabling companies to gain more profits.

Advanced process control training programs are offered for to-be process control operators and engineers. The goal is to educate the students in the entire APC system.

What’s an Advanced Process Control Training program?

The APC training program is an instructor-led and 100% helpful program organized by many platforms. The lessons are rich in practical examples and features hands-on lessons. Lessons are provided through both online sessions and in-class sessions, giving you both the options to choose from. A student can understand the important concepts of the APC as everything is included in the course.

Who should enroll in the APC training program?

The training program is intended for engineers, process control operators, process engineering experts, PID controllers, control loop tuning operators, and anyone who wants to understand the process control system. The course is designed to provide students with sufficient knowledge and in-hand practice lessons to make them efficient for operating the APC system. This course is applicable to technical and supervisory personnel as well. You can apply the gained knowledge (from the course) in the industry you work for.

Benefits of Advanced Process Control Implementation

The advent of Advanced Process Control delivers the perfect combination of an increase in productivity and profitability while saving energy costs. The introduction of APC technology has brought about a revolution in the manufacturing industries.

Back in the days, engineers had to spend a lot of time with less sophisticated tools to perform their technical tasks. It was all because of the lack of cutting-edge technology systems and software. Thanks to the advancement of technology, now, everything has become less complicated. Now, operators, technicians, and engineers do not have to rely on outsiders to perform APC-related tasks and utilize technology.

The greatest thing about APC implementation is; it offers several benefits.

· It improves process safety

· Reduces environmental emissions

· Increases productivity

· Maximizes profitability

· Makes the tasks simpler and easier

· Reduces energy costs

· Improves operational efficiency

· Delivers the best results

Understanding process control solutions shouldn’t have to difficult as Advanced Process Control Training programs are provided by many websites.

Pi Control Solutions offers training programs related to APC, Model Predictive Control, Control Loop, etc. You can visit the website, browse it, and register online to join a course.